Epoxy Flooring with Aluminum Oxide: The Ultimate Slip-Resistant Solution

Epoxy Flooring with Aluminum Oxide: The Ultimate Slip-Resistant Solution

Epoxy flooring with aluminum oxide enhances slip resistance by adding a durable, textured surface. Perfect for wet, oily, and high-traffic areas, it significantly reduces the risk of slip-and-fall accidents.

- Increased Grip: Up to 50% more slip resistance compared to standard epoxy.

- Durability: Resistant to wear, foot traffic, and industrial spills.

- Customizable Texture: Available in fine, medium, coarse, and extra-coarse grit sizes.

Upgrade your floors today with epoxy flooring infused with aluminum oxide for unmatched safety and longevity.

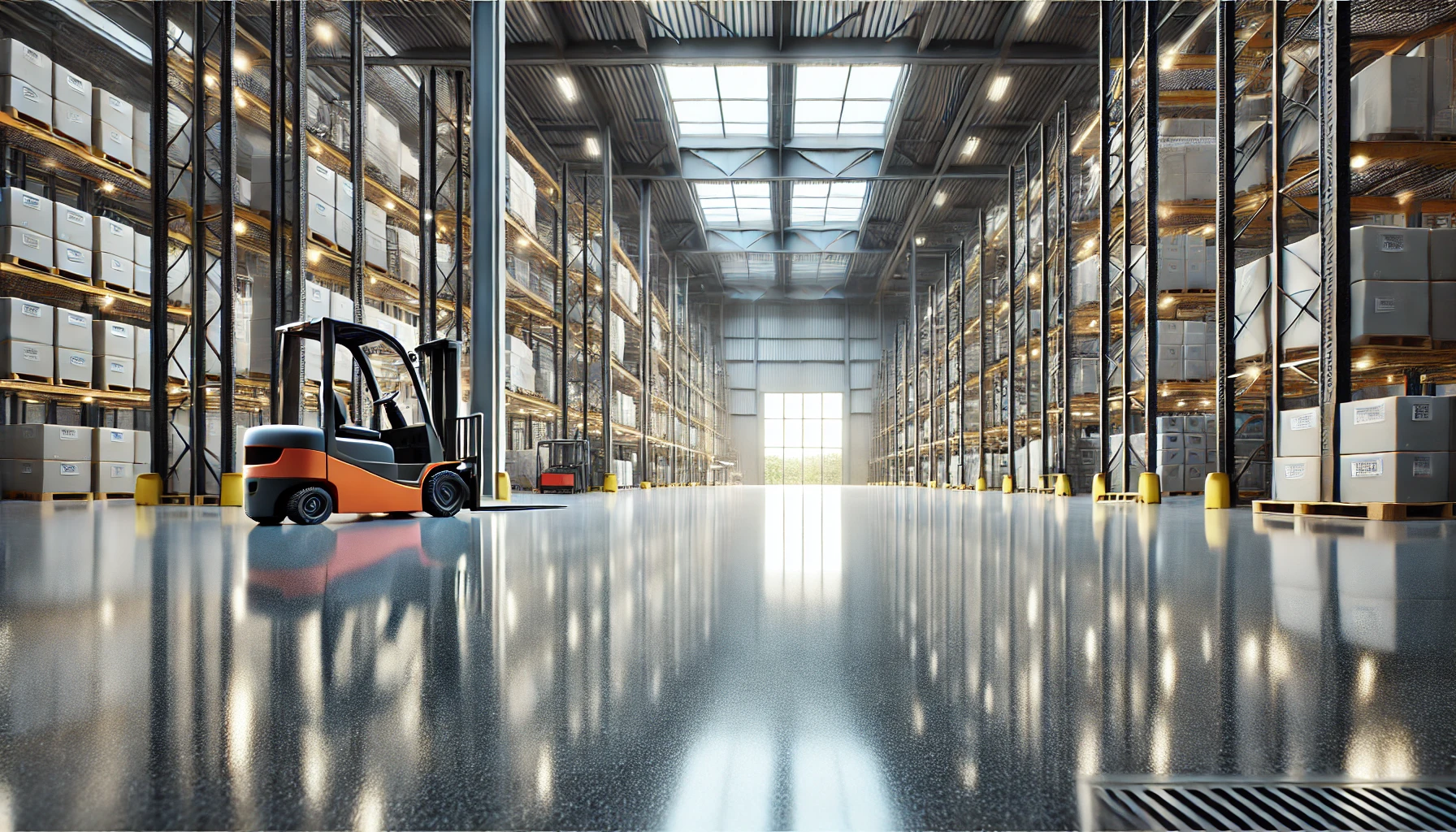

When you need an epoxy floor that can handle wet, oily, or high-traffic areas, epoxy flooring with aluminum oxide is the best solution. You get unmatched slip resistance, extreme durability, and a surface built to last. Whether you run a commercial kitchen, an industrial warehouse, or a garage, you need traction you can trust.

In this guide, you’ll learn how epoxy flooring with aluminum oxide enhances traction, how different grit sizes impact slip resistance, and how to properly disperse aluminum oxide in your epoxy for a flawless finish.

How Aluminum Oxide Enhances Traction in Wet or Oily Environments

If you’ve ever walked on a wet floor and felt your feet slide out from under you, you know how dangerous a slippery surface can be. Epoxy flooring with aluminum oxide prevents that by adding an ultra-durable, textured surface that grips even in the toughest conditions.

What Makes Aluminum Oxide Special?

- Hardest Commercially Available Abrasive: You get a surface that’s tough enough to withstand constant foot and vehicle traffic without wearing down.

- Excellent Grip: Unlike sand or silica, aluminum oxide maintains high traction even when exposed to oil, water, or cleaning chemicals.

- Long-Lasting Durability: Your epoxy floor stays slip-resistant for years, with minimal maintenance required.

How Well Does Aluminum Oxide Improve Slip Resistance?

A study by the National Floor Safety Institute (NFSI) found that adding aluminum oxide to epoxy coatings can increase the coefficient of friction (COF) by up to 50% compared to standard epoxy floors. This means your floor will provide significantly better grip in wet or greasy conditions, reducing slip-and-fall risks.

| Flooring Type | Coefficient of Friction (COF) | Slip Resistance Rating |

|---|---|---|

| Standard Epoxy Floor | 0.40 | Low |

| Epoxy with Fine Aluminum Oxide | 0.55 | Moderate |

| Epoxy with Medium Aluminum Oxide | 0.65 | High |

| Epoxy with Coarse Aluminum Oxide | 0.80+ | Very High |

If your floor is regularly exposed to water, grease, or industrial spills, using epoxy flooring with aluminum oxide is one of the best ways to improve safety.

Comparing Grit Sizes of Aluminum Oxide and Their Impact on Slip Resistance

Choosing the right grit size for epoxy flooring with aluminum oxide is crucial for balancing slip resistance and floor aesthetics. The size of the aluminum oxide particles directly affects the texture of the epoxy surface.

Understanding Grit Sizes

Aluminum oxide is available in different grit sizes, ranging from fine (100+ grit) to coarse (20-40 grit). Here’s how each size impacts your epoxy flooring:

| Grit Size | Texture Level | Best For | Slip Resistance Level |

|---|---|---|---|

| 100+ Grit | Very Fine | Light Foot Traffic, Decorative Finishes | Moderate |

| 60-80 Grit | Medium | Commercial Kitchens, Wet Areas | High |

| 40-60 Grit | Coarse | Warehouses, Auto Shops, Industrial Use | Very High |

| 20-40 Grit | Extra Coarse | Heavy-Duty Areas, Loading Docks | Extreme |

Choosing the Right Grit Size for Your Needs

- For Homes & Light Commercial Use → 80-100 grit

- For Restaurants & Commercial Kitchens → 60-80 grit

- For Warehouses & Manufacturing Facilities → 40-60 grit

- For Extreme Industrial Use (Oil Rigs, Loading Docks, etc.) → 20-40 grit

The coarser the grit, the better the traction, but it will also make cleaning a bit more challenging. Finding the right balance is key.

Proper Dispersion Techniques to Maintain Even Distribution and Aesthetics in Epoxy Coatings

You can’t just dump aluminum oxide into your epoxy and hope for the best. Proper mixing and application techniques ensure that epoxy flooring with aluminum oxide remains evenly textured and visually appealing.

3 Proven Ways to Disperse Aluminum Oxide in Epoxy

1. Mix-In Method (Best for Light to Medium Textures)

- Add aluminum oxide directly into the epoxy mixture before application.

- Stir continuously to ensure even distribution.

- Apply the epoxy using a roller or squeegee.

✅ Best for: Moderate slip resistance in residential or commercial applications.

2. Broadcast Method (Best for High-Traction Floors)

- Apply a wet base coat of epoxy.

- Evenly broadcast aluminum oxide over the surface.

- Allow the epoxy to absorb the grit before applying a topcoat.

✅ Best for: Industrial areas where epoxy flooring with aluminum oxide needs maximum slip resistance.

3. Trowel-In Method (Best for Heavy-Duty Applications)

- Blend aluminum oxide into epoxy mortar and trowel it onto the surface.

- Creates a dense, high-traction flooring system.

✅ Best for: Warehouses, auto shops, and areas exposed to heavy machinery and oils.

Pro Tips for Achieving the Best Results

- Use the Right Amount: Too much aluminum oxide can make the epoxy difficult to apply and lead to an overly rough surface.

- Maintain Consistent Mixing: Uneven distribution can lead to patchy traction, making some areas slicker than others.

- Seal with a Topcoat: A final epoxy layer ensures the aluminum oxide stays embedded while maintaining a clean appearance.

Why You Should Choose Epoxy Flooring with Aluminum Oxide

If you need a slip-resistant, durable, and long-lasting flooring solution, epoxy flooring with aluminum oxide is the clear winner.

✔ Reduces Slip-and-Fall Accidents – Ideal for wet, oily, or high-traffic areas.

✔ Withstands Heavy Wear – The hardest grit additive available.

✔ Works for Any Environment – Perfect for homes, businesses, and industrial sites.

✔ Requires Minimal Maintenance – Stays effective for years without losing traction.

Get Expert Help for Your Epoxy Flooring Needs

If you’re looking for epoxy flooring with aluminum oxide that delivers top-tier slip resistance and durability, check out Crystal Clear Epoxy. Their team can help you choose the right grit size and application method for your space.

Don’t settle for slippery, unsafe floors. Upgrade to epoxy flooring with aluminum oxide today!

Frequently Asked Questions

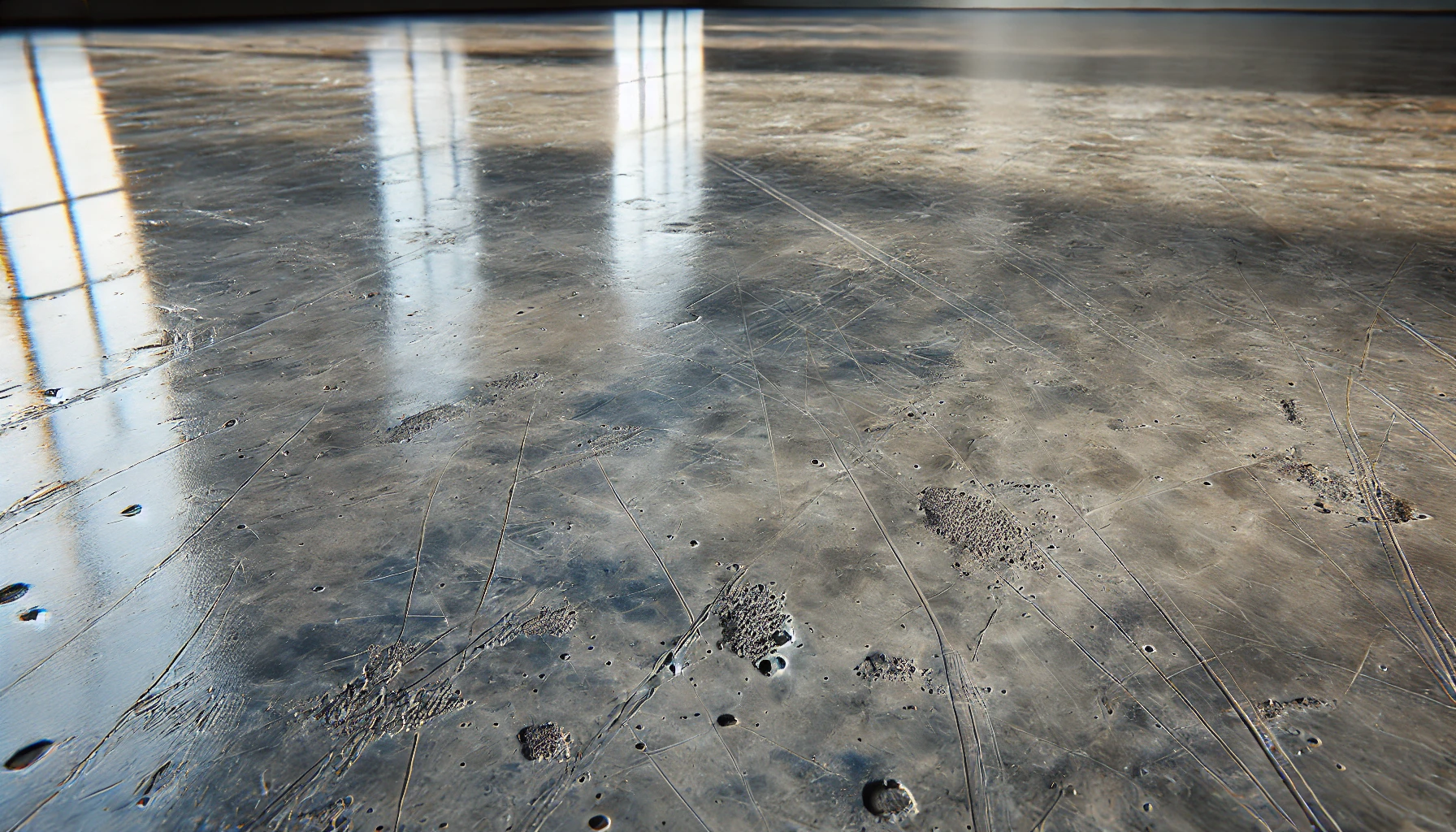

Can the addition of aluminum oxide affect the aesthetics of epoxy flooring?

Yes, incorporating aluminum oxide will introduce a textured finish to the epoxy floor, which may alter its appearance. While this enhances slip resistance, it's essential to consider the desired aesthetic outcome when selecting the grit size and application method.

Is aluminum oxide suitable for all types of epoxy flooring applications?

Aluminum oxide is versatile and can be used in various settings, from residential garages to industrial warehouses. However, the choice of grit size and application technique should align with the specific requirements of the environment to ensure optimal performance.

How does aluminum oxide compare to other slip-resistant additives like silica sand?

Aluminum oxide is harder and more durable than silica sand, offering superior slip resistance, especially in wet or oily conditions. Its longevity and effectiveness make it a preferred choice for environments where safety and durability are paramount.

Will adding aluminum oxide make the epoxy floor harder to clean?

Cleaning GuideA coarser texture can make cleaning slightly more challenging, as dirt and debris may accumulate in the textured surface. However, regular maintenance and appropriate cleaning techniques can effectively manage this.

Does the incorporation of aluminum oxide affect the durability of epoxy flooring?

Yes, aluminum oxide enhances the durability of epoxy flooring by providing a wear-resistant surface that withstands heavy foot and vehicle traffic, extending the floor's lifespan.